Virtual Design & Construction

Bancroft’s Virtual Design & Construction (VDC) team has a goal of maximizing efficiency and boosting collaboration for each of Bancroft’s projects. Our VDC team accomplishes this by utilizing the latest in value-added construction methodology and technology to help overcome any construction challenges.

Set Our Projects Up For Success

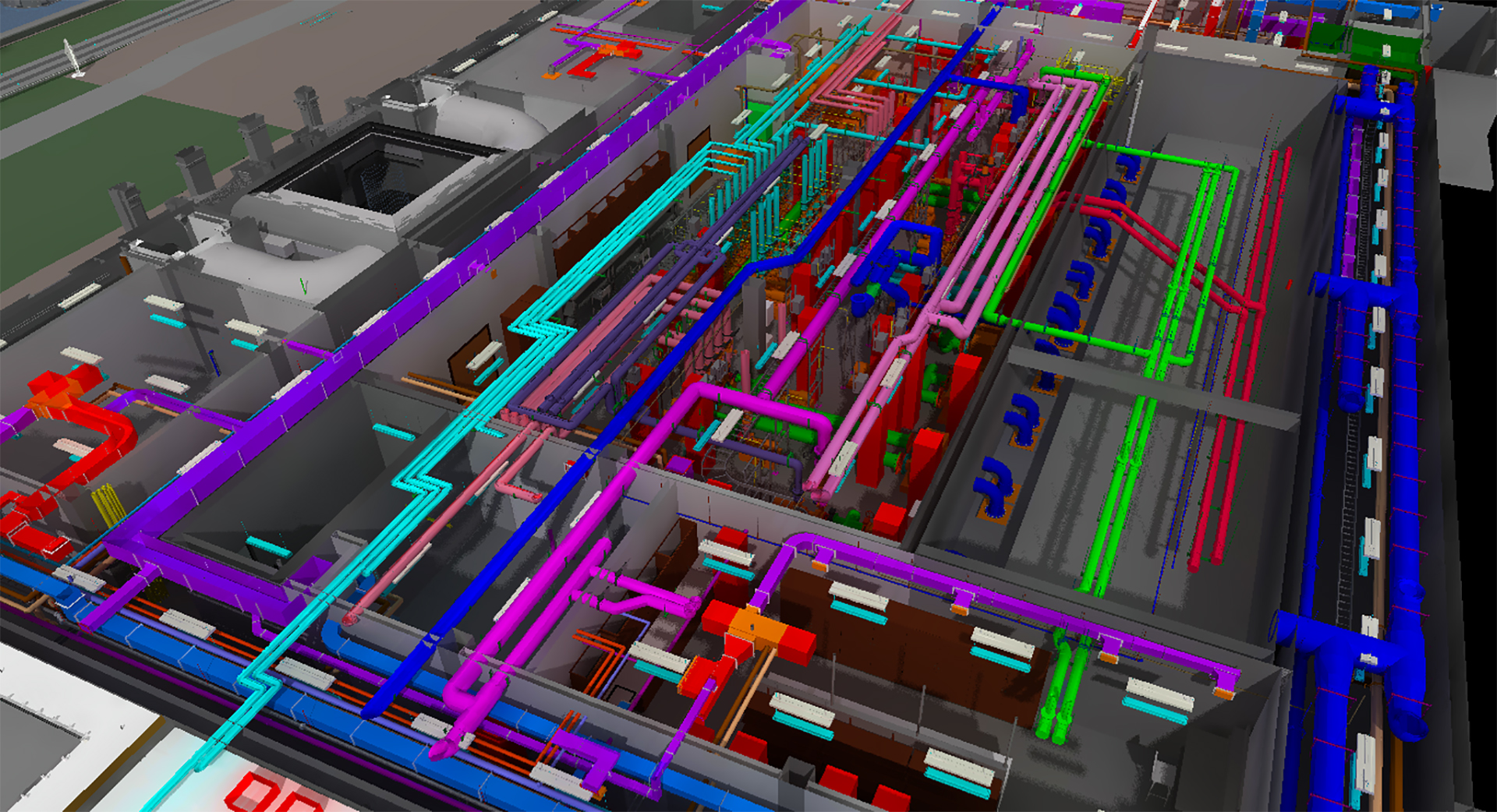

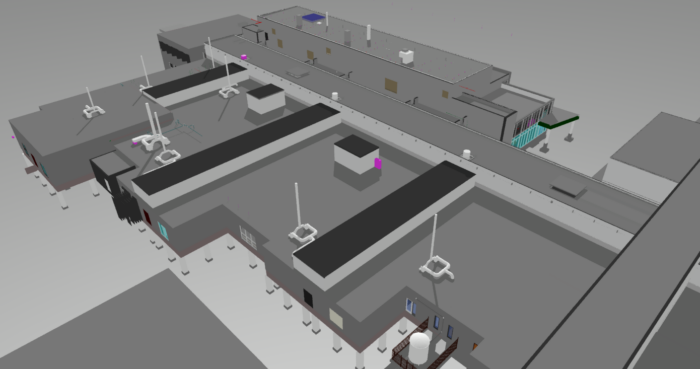

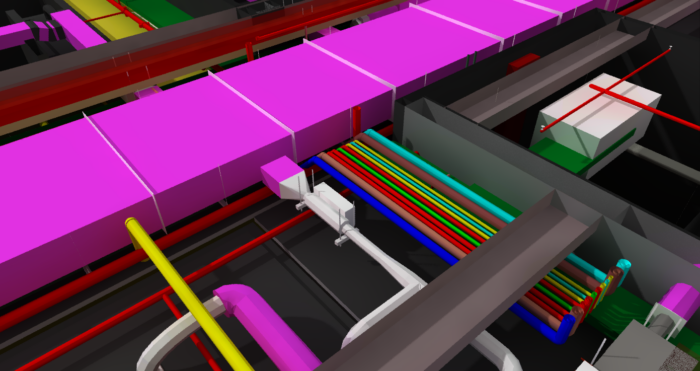

BIM and Cell Biologics

The Cell Molecular Biologics Facility project consisted of a renovation and addition to a laboratory and office facility in Central New Jersey for a Fortune 100 Pharmaceutical Company. Since the scope of work involved the installation and renovations of HVAC systems, medical gas services and biohazard waste systems, Virtual Design and Construction (VDC) played an instrumental role in the planning, coordination, and delivery of the project, including:

Planning & Coordination

In order to meet the demands of a tight schedule, BIM 360 (an online collaboration tool), was utilized in order to simultaneously design and coordinate the 3D Design Model. Each contractor uploaded and appended their shop drawings to the project’s central BIM model for real-time coordination.

At the end of each design milestone, Bancroft reviewed the BIM 360 Central Model in Navisworks to resolve any issues or clashes found throughout the model. Through this process, Bancroft resolved over 40,000 clashes.

Thinking with the End in Mind

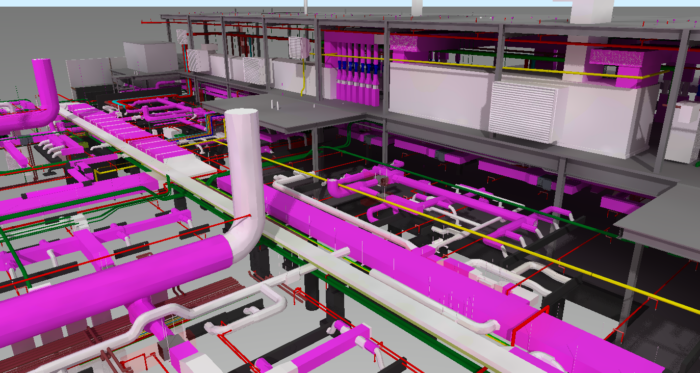

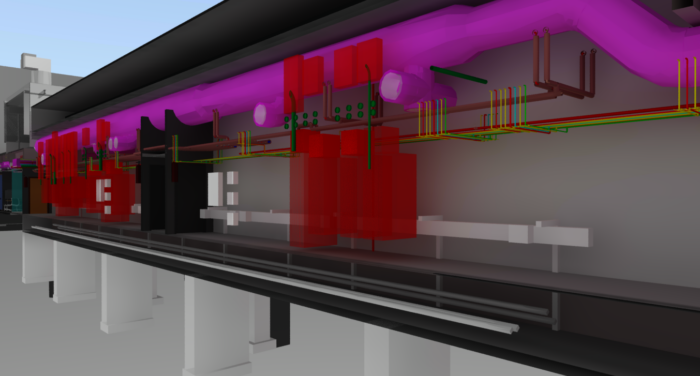

While analyzing the Model, Bancroft realized that, after the project was completed and turned over to the facilities group, access to the equipment throughout the service corridors was going to be difficult. This was due to the amount of large diameter piping running underneath and around the equipment. Therefore, Bancroft worked with the design team and determined that there was enough space below the raised floors of the corridors to run the piping. This change resulted in the mitigation of potential changes in the field.

Virtual Visualization

Due to the fact that some of the existing above-ceiling MEP services were going to remain throughout the building, a 3D visualization of the soon-to-be installed MEP services throughout the same space showed that many areas were going to be too congested. Therefore, Bancroft designed options for lowering the ceiling grid in certain areas to allow for more room to install new piping. These options were presented to and approved by the design team before the start of construction.

Real-Time Field Verification

Utilizing BIM 360 Mobile, field superintendents were able to take the 3D Model into the field on their iPads. This allowed each contractor to conduct real-time field verification of the coordinated systems.

Interested In How Our VDC Group Can Assist You?

Make sure to reach out to Bancroft’s VDC Manager, Dave Johnson, at djohnson@bancroftusa.com